Mechanical Engineering

Full-time

With placement

Three year

Four year

September 2026

In a nutshell

This programme prepares you to become a confident and adaptable mechanical engineer, ready for modern industry. At Salford, you will build strong foundations in core mechanical engineering, then progress to advanced study in automation and robotics, advanced manufacturing, sustainable energy systems, and electrified transportation. You will learn to design, analyse, simulate, and validate complex mechanical systems using industry-standard tools such as CAD, CFD/FEA, MATLAB, supported by extensive laboratory and workshop activity.

What makes this course different is its strong focus on real engineering practice. You will complete hands-on design projects every year, including team-based challenges and an individual research project, reflecting professional engineering environments. Automation and robotics, digital engineering, sustainability, ethics, and systems thinking are embedded throughout the programme, preparing you to make responsible engineering decisions across sectors such as energy, transport, manufacturing, aerospace, and other industries.

Employability is central to this course. You will develop technical expertise alongside project management, teamwork, and communication skills. An optional industrial placement allows you to gain valuable workplace experience and strengthen your career prospects.

This programme is accredited by Royal Aeronautical Society.

Looking to take your studies further? Take a look at our integrated masters MEng pathway.

Start your study journey

Register for our next Open Day to learn more about studying Mechanical Engineering, explore our facilities and meet the course team

You will:

- Design and analyse complex mechanical systems using industry-standard software.

- Develop practical skills through hands-on laboratory work, workshops, and real engineering design projects.

- Gain experience in automation, robotics, and advanced manufacturing for modern industrial applications.

- Apply sustainability, ethics, and systems thinking to responsible mechanical engineering design.

- Build project management, teamwork, and communication skills through individual and group projects.

- Enhance employability through optional industrial placement and exposure to professional engineering practice.

options available

students accepted

This is for you if...

You are interested in automation, robotics, advanced manufacturing, sustainability, energy, and electrification shaping modern mechanical engineering careers.

You enjoy applying mathematics and physics to solve real engineering problems.

You want strong employability through hands-on projects and an optional industrial placement.

You are motivated by sustainable, ethical, and socially responsible engineering practice.

You want this course to prepare you for careers across energy, transport, manufacturing, aerospace, and other industries.

You want an accredited BEng degree in engineering.

All about the course

This programme is delivered over three years, or four years if you choose to include an industrial placement. It is structured to build your knowledge progressively, from core mechanical engineering principles to advanced undergraduate study and professional practice.

In the first year, you will develop strong foundations in engineering mathematics, materials, structures, dynamics, thermofluids, manufacturing, and computer-aided design. Learning is supported by laboratories, workshops, and team-based design projects that introduce engineering problem solving and professional skills.

In the second year, you will deepen your understanding of mechanical systems through subjects such as dynamics and control, thermofluids and CFD, structural mechanics and FEA fundamentals, manufacturing and quality control, and computer-aided engineering. Group design projects continue, reflecting real engineering practice and teamwork.

In the final year, you will study advanced undergraduate topics including robotics and advanced manufacturing systems, power and energy technologies, electrified and hybrid drivetrains, and applied structural and thermofluid analysis. You will also complete a substantial individual project, applying analysis, simulation, and experimental methods to a real engineering problem.

Teaching combines lectures, tutorials, laboratories, and project-based learning, with a strong emphasis on practical experience and collaboration. An optional industrial placement between years two and three allows you to gain professional experience, apply your learning in industry, and strengthen employability.

The very popular Salford Racing student society can be found on Instagram and closely aligns with this programme..

CAD, Mechanical Group Design and Management

This module introduces key skills in mechanical design, CAD, project management, and workshop practice. Working in teams, students will take part in a group project based on the IMechE Design Challenge, developing communication, teamwork, and project management skills throughout the process. Students will learn CAD modelling, engineering drawing, and design principles, along with project planning, risk management, and resource allocation in an applied setting. Practical sessions cover core workshop techniques and hand skills essential for engineering practice. The module emphasises real-world engineering by integrating technical, commercial, and organisational factors. Assessment is through group reports and presentations, combining theoretical knowledge with practical application in a collaborative engineering context.

Engineering Dynamics and Electrical Systems

This module introduces core principles of Engineering Dynamics and Electrical Engineering, applying mathematics, natural science, and engineering methods to analyse motion and electrical systems. Kinematics, kinetics, Newton’s laws, energy principles, and circuit theory are used to model linear and rotational systems, recognising limitations of techniques. Activities include interpreting technical literature, investigating systems using laboratory skills, and selecting appropriate materials, equipment, and technologies with awareness of constraints. Circuit diagrams and behaviours under DC and AC supplies are analysed. Emphasis is placed on effective communication in technical contexts, and on planning and recording self-directed learning as a foundation for lifelong development.

Engineering Structures and Engineering Materials

This module introduces key principles of engineering materials and structural analysis. It covers stress, strain, beam theory, torsion, thermal stresses, frameworks, and Mohr’s circles for stress and strain analysis in two- and three-dimensional components. Students will explore material testing, properties through bonding mechanisms, strengthening methods, phase diagrams, heat treatment, and corrosion principles and protection. The types and use of polymer materials will be included. Emphasis is placed on the relationship between material structure and performance, and on applying analytical methods to real-world problems. Laboratory sessions support hands-on learning, while assessments include coursework, and coursework to develop skills in selecting materials and analysing simple structures in mechanical engineering contexts.

Fundamentals of Engineering Mathematics

This module develops core mathematical concepts, notation, and techniques essential for solving complex engineering problems. It reinforces prior knowledge and introduces calculus and algebra to support the application of engineering principles. Emphasis is placed on selecting and applying appropriate analytical techniques, using first principles where necessary, and recognising their limitations. Mathematical knowledge is applied to reach substantiated conclusions across a range of engineering contexts. The module also establishes a foundation for further mathematical study and supports the development of lifelong learning and self-directed development, forming the basis for continued professional development (CPD) in engineering.

Manufacturing Methods and Processes

This module introduces fundamental manufacturing processes such as casting, forming, machining, and finishing. It explains how materials behave during production and how to choose suitable methods for different applications. Key concepts such as production cost, efficiency, and sustainability are explored, with attention to the environmental and societal impact of manufacturing decisions. The module highlights safety awareness and introduces basic risk identification in industrial settings. It also covers the principles of quality control and continuous improvement. Engineering management and commercial aspects are introduced to provide a broader understanding of modern manufacturing practice within professional engineering environments.

Thermofluid Fundamentals

This module introduces core principles of thermodynamics and fluid mechanics, applying mathematics, natural sciences, and engineering principles to complex problems. Key topics include energy transfer, fluid behaviour, and the use of analytical and computational techniques for thermofluid modelling, with attention to methodological assumptions and limitations. Emphasis is placed on evaluating technical literature and data sources to support engineering analysis, and on developing practical investigation skills through laboratory work. Broader considerations such as sustainability, safety, and system performance are addressed. The module also supports effective communication and encourages reflective practice and professional development.

Engineering Mathematics

This module extends core mathematical knowledge by introducing a broader range of techniques relevant to the analysis and solution of complex engineering problems. Key topics include differential equations, numerical methods, partial differentiation, determinants, matrices, Laplace transforms, and functions of a complex variable. Emphasis is placed on the accurate selection and application of analytical and computational methods, recognising their limitations within engineering contexts. Mathematical principles are developed through lectures, with discipline-specific sessions offering applied examples. Problem-solving seminars support the use of first principles and the development of confidence in modelling and interpreting engineering systems.

Engineering Dynamics and Control Engineering

This module introduces the principles and techniques for the design and analysis of dynamic systems and feedback control. It applies knowledge of mathematics, statistics, natural science, and engineering principles to model and analyse complex mechanical problems. Emphasis is placed on selecting and applying appropriate computational and analytical techniques, recognising their limitations. Technical literature and standards are evaluated to support the solution of complex problems. Practical laboratory and workshop skills are developed through experiments investigating system behaviour. Effective communication of engineering concepts is fostered, alongside planning and recording self-directed learning as part of continuing professional development.

CAE and Mechanical Group Design

This module integrates mechanical design with computer-aided engineering (CAE) through collaborative, open-ended group projects. It focuses on applying engineering principles to develop, model, and optimise design solutions. Emphasis is placed on system-level thinking, sustainability, ethics, and inclusive practice. Projects involve component selection, CAD modelling, simulation, risk awareness, and consideration of environmental and commercial factors. Students engage in teamwork, project management, and structured reporting, developing communication and leadership skills. The module reflects real-world design practice, encouraging technical decision-making based on legal, societal, and economic constraints, aligned with professional engineering standards.

Manufacturing, Quality Control and Simulation

This module covers manufacturing methods and industrial processes, with emphasis on selecting appropriate materials, technologies, and recognising their limitations. It explores quality management systems and continuous improvement within engineering contexts, along with the application of engineering management principles, commercial awareness, and legal considerations such as intellectual property. Simulation modelling and relevant computational techniques are introduced to support process analysis and optimisation. The module supports the design of effective, cost-efficient, and standards-compliant solutions, incorporates principles of risk evaluation and mitigation, and encourages collaboration, leadership, and individual effectiveness in engineering environments.

Structural Mechanics and FEA Fundamentals

This module develops a solid understanding of structural integrity, fitness for service, and the mechanical properties of materials and components. It introduces analytical methods for assessing structures under various loading conditions, including axial, bending, and torsional loads. Students will explore fundamental yield criteria and failure theories relevant to design. The module also covers the direct stiffness method as a basis for structural analysis and introduces the formulation and application of Finite Element Analysis (FEA). Composite systems are introduced, with emphasis on their structural behaviour and analysis techniques. Fitness for service and equipment life analyses are covered through various failure mechanisms including Fracture, Metal Fatigue and high temperature Creep. Strength and applications of engineering Aluminium alloys will also be covered through the topic of Age Hardening. Theoretical knowledge is reinforced through worked examples and computational tools.

Thermofluid and CFD Studies

This module deepens understanding of thermodynamics and fluid mechanics, addressing more complex problems involving entropy, refrigeration cycles, renewable energy systems, turbomachinery, and computational fluid dynamics (CFD). It applies mathematical, and engineering principles to realistic scenarios using first-principles-based analysis and modelling. A range of analytical and computational techniques are employed with critical awareness of their assumptions and limitations, supported by evaluation of technical literature and data. Practical investigation through laboratory experiments and simulation enhances system-level insight. The module also develops the ability to communicate technical findings effectively and includes structured reflection to support continuous improvement and professional development.

FEA and Structural Mechanics

The module focuses on two core areas: Finite Element Analysis (FEA) and Structural Mechanics. FEA provides a computational technique to model complex problems by discretising structures into elements with predictable behaviour. These elements are assembled to simulate the response of entire systems, using principles of mathematics and engineering. Structural Mechanics builds on this by applying first principles to analyse statically indeterminate structures, beams on elastic foundations, and thick and thin-walled pressure vessels. Plate theory is also introduced. The module supports the application of analytical and computational techniques, encourages systems thinking, and promotes the evaluation of technical literature in solving complex problems.

Mechanical Design of Electrical and Hybrid Drivetrain

This module develops knowledge and skills in integrated powertrain technologies and engineering management for solving complex problems in sustainable transport. It covers internal combustion engines, hybrid and electric drivetrains, fuel cells, battery systems, power electronics, engine management, and vehicle control. Analytical and computational methods are applied with consideration of their limitations, supported by first-principles modelling and technical literature. Practical understanding is enhanced through laboratory work and a design activity focused on fuel cell systems. The module promotes systems thinking, sustainability, risk and security mitigation, inclusive engineering practice, quality assurance, project management, effective teamwork, leadership, and continuous professional development (CPD).

Robotics and Advanced Manufacturing Systems

This module explores industrial robotics and automation, focusing on their application in modern manufacturing. It covers robot kinematics, dynamics, control, sensing, and programming, alongside practical use of Programmable Logic Controllers (PLCs), Distributed Control Systems (DCS), and Supervisory Control and Data Acquisition (SCADA). Students apply appropriate technologies while recognising their limitations, evaluate societal and environmental impacts, and address ethical concerns. The module promotes inclusive engineering practices, continuous improvement through quality management, and effective teamwork. Broader topics include Industry 4.0, human-robot collaboration, and economic and security aspects of automation, preparing students for professional roles in advanced manufacturing environments.

Thermofluid for Power Systems

This module develops the application of thermodynamics and fluid mechanics to complex power system problems. It covers gas and vapour cycles, mixtures, air conditioning, combustion, inviscid and irrotational flows, boundary layers, drag, lift, open-channel flow, and compressible duct flow (Rayleigh and Fanno). Mathematical and scientific principles are applied using first-principles modelling. Analytical and computational techniques, including turbulent CFD, are used with awareness of limitations. Technical literature supports evaluation. Laboratory and simulation activities enhance practical understanding. The module also builds skills in communicating complex engineering concepts and includes structured reflection for continuous development and lifelong learning (CPD).

Individual Project

The individual project involves working independently on a substantial research or industrially relevant task, requiring critical evaluation of technical literature and other reliable sources of information. It promotes the application of an integrated or systems-based approach to solve complex engineering challenges. The work considers environmental and societal impacts, encouraging the development of solutions that minimise adverse effects. Ethical issues are identified and addressed through reasoned decision-making guided by professional codes of conduct. Risk is assessed and managed using structured processes. The project also develops skills in engineering management, commercial awareness, legal frameworks, effective communication, and continuous professional development.

We take a flexible approach to our course delivery that promotes diversity and inclusivity and provides a blended learning experience, which will vary to meet specific programme requirements. This learning time includes formal lectures and interactive activities such as seminars, tutorials, practical sessions, laboratory and studio learning. Smaller classes may be used to support collaborative activities such as project and group work and presentations. A range of different assessments and feedback is offered to meet the needs of both our diverse student body and specific subject needs.

Our undergraduate courses are normally made up of 20 credit modules which are equal to 200 hours of learning time. A three-year degree qualification typically comprises a total of 360 credits (120 credits per year).

Please note that exact modules and content offered may vary in order to keep content current and, for courses that offer optional modules, may depend on the number of students selecting particular options. When accepting your offer of a place to study on a programme with optional modules, you should be aware that optional modules may not all run each year. Your tutor will be able to advise you as to the available options on or before the start of the programme. Whilst the University tries to ensure that you can undertake your preferred options, it cannot guarantee this.

Frequently asked questions

What is mechanical engineering?

Mechanical Engineering is a branch of engineering that studies physical machines and designs and maintains mechanical systems. This branch of engineering combines engineering physics and mathematics principles with materials science. This is a helpful explanation.

What do mechanical engineers do?

Mechanical engineers play a key part in our daily lives, studying, designing, and maintaining mechanical systems. They work on any item that has a system of moving parts. The field combines engineering physics and mathematics principles with materials science to shape the things we use every day, from heating systems to refrigerators to cars.

Is mechanical engineering hard?

The workload in a mechanical engineering programme is notoriously intense. Juggling multiple courses, assignments, and projects necessitates effective time management. This is because the pressure to meet deadlines and excel in coursework can be overwhelming.

Are Mechanical engineers in demand?

Yes, mechanical engineers are generally in demand. The field is expected to see continued growth, with job openings projected to increase in the coming years. This demand is driven by the need for engineers in various industries, including manufacturing, automotive, and construction.

What jobs can you get with a mechanical engineering degree?

- Aerospace engineer.

- Automotive engineer.

- CAD technician.

- Contracting civil engineer.

- Control and instrumentation engineer.

- Maintenance engineer.

Is mechanical engineering a good job?

A career in mechanical engineering can be very rewarding. If you choose to go down this career path, you could play an important role in the research, design, and maintenance of key mechanical projects that shape modern life.

School of Science, Engineering and Environment

Rising to the challenge of a changing world, our degree courses are designed to shape the next generation of urbanists, scientists, engineers and industry leaders.

Driven by industry, and delivered by supportive programme teams, you can develop the knowledge and skills to become unstoppable in your career.

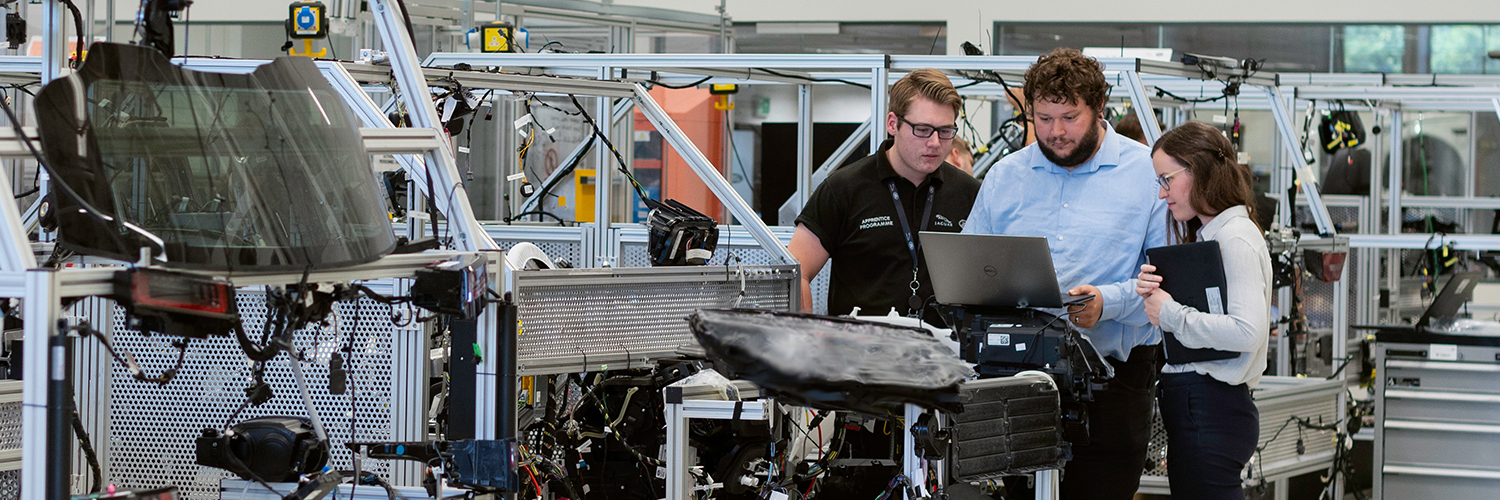

Facilities

As a mechanical engineering student, you will learn in specialist laboratories that support modern engineering education, applied research, and hands-on experimentation. These facilities allow you to develop practical skills alongside strong theoretical understanding, using equipment that reflects current and emerging industry practice. You will have access to the Morson Makerspace, a modern additive manufacturing and digital fabrication facility, and the GMIoT workshop, supporting design, prototyping, and testing activities.

You will also use a wide range of dedicated engineering laboratories, including:

- Mechanical and Aeronautical laboratory with wind tunnels, flight simulators, gas turbines, forced convection rigs, and wind testing facilities.

- Control laboratory equipped with control rigs and electronic systems.

- Light Structures laboratory for material strength, hardness, and structural deformation testing.

- Dynamics laboratory with equipment for vibration and dynamic response analysis.

- Composites laboratory focused on manufacturing composite structures, including carbon fibre.

- Thermofluids laboratory for air and water flow studies, fluid property analysis, engine testing, and hydrogen fuel cell power systems.

- Robotic lab equipped with industrial robots and mobile platforms.

- Automotive and Autonomous Vehicle Technology facilities, including emissions measurement, electric and hybrid vehicles, and chassis dynamometers.

During your Level 6 Individual Project, you are encouraged to make full use of these facilities to support experimental, design, and applied research work.

After your Mechanical Engineering degree

EMPLOYMENT

This course prepares you for a wide range of engineering careers across traditional and emerging sectors. When you graduate, you could work in roles such as mechanical engineer, design engineer, systems engineer, manufacturing engineer, robotics or automation engineer, energy engineer, or control and simulation engineer. Many graduates also progress into project engineering, technical consultancy, or research and development roles.

The strong focus on automation, digital engineering, sustainability, and hands-on design means you are well suited to industries such as energy, transport, aerospace, automotive, advanced manufacturing, and low-carbon technologies. The integrated master’s route also supports progression towards Chartered Engineer registration, opening pathways to senior technical and leadership roles over time.

Graduates from mechanical engineering programmes at Salford typically work for national and international employers across engineering and technology. These include organisations in aerospace, automotive, energy, manufacturing, and engineering consultancy, as well as small and medium-sized enterprises and start-ups. Some graduates choose to continue into doctoral research or specialist postgraduate study, while others use the skills gained on this course to move into innovation, entrepreneurship, or interdisciplinary engineering roles.

Overall, this course equips you with the technical depth, professional skills, and adaptability needed for a broad and resilient engineering career.

FURTHER STUDY

You might find you want to learn more about automation, mechanical engineering, and robotics. Building on our engineering expertise, we offer a range of postgraduate courses that can take your interests and career opportunities further. Salford graduates and alumni will also receive a generous fees discount.

Advanced Mechanical Engineering (MSc)

How to get accepted on the mechanical engineering course

APPLICANT PROFILE

We're looking for applicants who have studied mathematics or physics-based subjects at college. You will ideally already have an interest in mechanical engineering related matters and desire a future career in this field. You are a keen problem-solver who enjoys a blend of mathematics, theoretical principles, design, computer work, and laboratory work.

ENGLISH LANGUAGE REQUIREMENTS

All of our courses are taught and assessed in English. If you are an international student and not from a majority English speaking country, you will need IELTS 6.0 with no element below 5.5. We also accept a range of other English language qualifications.

If you do not have the English language requirements, you could take the Pre-Sessional English course, or the International Foundation Year to gain entry onto this degree.

GCSE

English Language and Mathematics at grade C/level 4 or above.

UCAS tariff points

104-112 UCAS points

A level

Two full A-levels required as a minimum, to include Grade C in Maths and an E in a Numerate Science (Physics, Chemistry, Electronics, Design Technology, Computer Science, statistics).

BTEC National Diploma

Grade DMM required from Engineering or Applied Science. Not accepted: Electrical Engineering, Aviation Operations

T level

Overall grade M

Must be in one of the following subjects:

- Design and Development for Engineering and Manufacturing Maintenance

- Installation and Repair for Engineering

- Manufacturing Engineering, Manufacturing, Processing and Control

Must have passed all components

Access to HE

104-112 UCAS points from a QAA-approved Engineering or Science course

Scottish Highers

Two Scottish Higher Levels required, including Maths and Physics.

Irish Leaving Certificate

Two Higher Levels required, including Maths and Physics

International Baccalaureate

30 points overall, including Grade 5 in Higher Level Maths and Physics (or a numerate Science). Must have passed the full International Baccalaureate to be considered.

International students

We accept qualifications from all around the world. Find your country to see a full list of entry requirements. If you do not have the English language requirements, you could take the International Foundation Year to gain entry onto this degree.

Salford Alternative Entry Scheme (SAES)

We positively welcome applications from students who may not meet the stated entry criteria but who can demonstrate their ability to pursue the course successfully. Once we receive your application, we'll assess it and recommend it for SAES if you are an eligible candidate.

There are two different routes through the Salford Alternative Entry Scheme and applicants will be directed to the one appropriate for their course. Assessment will either be through a review of prior learning or through a formal test.

To be considered for the Salford Alternative Entry Scheme you must have already achieved or be working towards GCSE Maths and English Grade C/4 (or equivalent).

Please contact Admissions for further information.

The cost of studying Mechanical Engineering

| Type of study | Year | Fees |

|---|---|---|

| Full-time home | 2026/27 | £9,790 per year |

| Full-time international | 2026/27 | £18,120 per year |

Tuition fees will increase in the second and each subsequent year of your course by the rate of inflation, subject to the maximum fee limits set out by the UK Government.

Additional costs

You should consider further costs which may include books, stationery, printing, binding and general subsistence on trips and visits.

International student scholarships

If you are a high-achieving international student, you may be eligible for one of our scholarships to study mechanical engineering.

Learn more about our latest international scholarships.

All set? Let's apply

Enrolment dates

Student information

Terms and conditionsUCAS information

Course ID H304

Institution S03