AHPs’ Day: The 3D printed feet helping give Salford podiatry students a leg up

Today, Friday 14 October, is Allied Health Professions (AHPs’) Day, and we’re celebrating by sharing some of the fantastic successes achieved by our AHP students and colleagues.

During the early days of the pandemic, like the rest of the world, the University of Salford’s Podiatry Clinic faced multiple challenges in the delivery of their teaching. Before Covid-19, podiatry students had rehearsed practical tasks, such as dressing wounds and assessments, using each other’s feet as models. Academics now had to find a new way to demonstrate these tasks on physical feet, whilst adhering to social distancing guidelines to keep students safe.

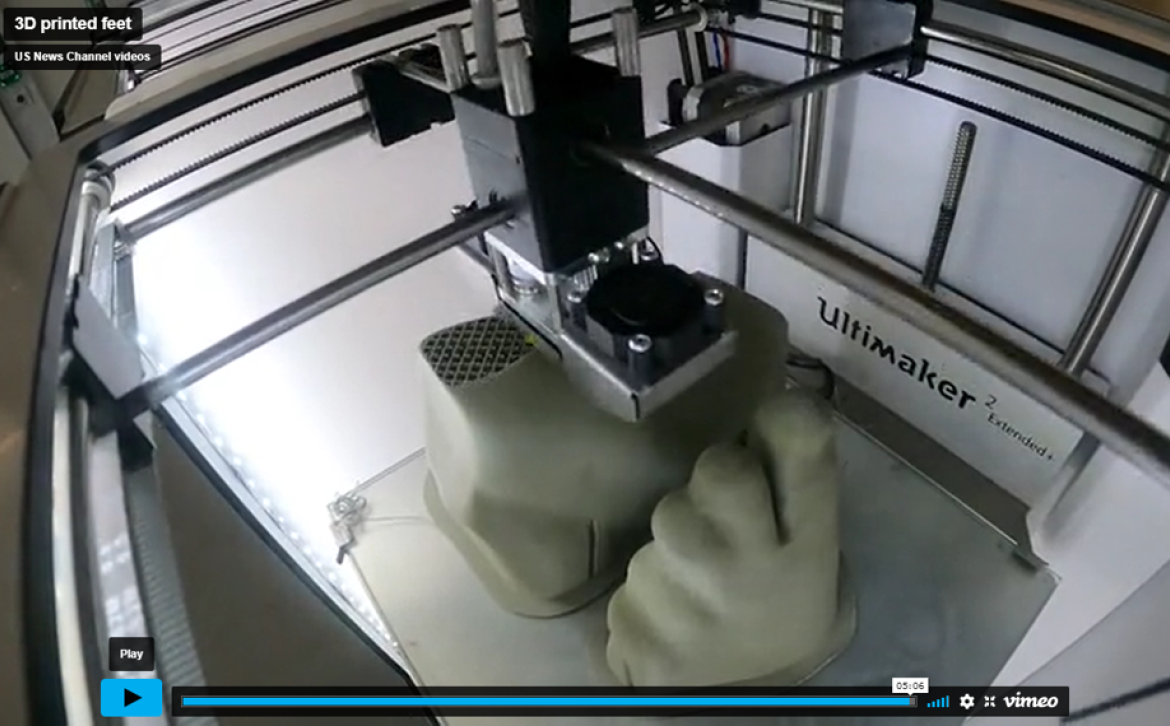

Podiatry technician, Susan Millidge, was set the difficult task by her subject lead, Veronica Newton, to create something similar to a prototype Veronica had seen being used in Australia. With nothing but a photo to work from, and no option to buy model feet due to budget restrictions, Susan and Veronica explored the idea of 3D printing. This idea turned into a “real success” after Susan discovered the University’s Maker Space programme.

The Maker Space is a digital fabrication hub open to all students and colleagues at the university to develop design and making skills. The team facilitate collaboration, help innovate traditional teaching and research processes, and problem solve with new technologies and digital methods. They provide skills, knowledge and full access to industry standard equipment including 3D printing, laser cutting and CNC machining to solve design and manufacturing challenges.

Working with George Dodgson and Rachel Norton from Maker Space, Susan discovered that the cost to create something in-house would be just £20-30 per foot being printed, in comparison to a £500 retail price. “We put it on the 3D machine to see what would happen – and that was the beginning of the project!”

After countless prototypes, they finally created the perfect 3D printed foot. As well as being cost-effective, the product was sustainable, with the inside of the feet being made from recycled milk bottles. The rest of the materials are also 100% recyclable and sustainable, meaning the project is also an important green initiative.

Podiatry students had the chance to test out the initial prototypes in workshops, with the feet receiving nothing but positive feedback. Susan explained: “Some students were even saying they were very jealous and wished they could have had the feet to use when they were in their first year. I’m so happy I pushed this project as far as I did because I feel the results are truly outstanding.”

The prototypes have continued to develop, with George and Susan working together to incorporate feedback and new ideas to make the feet even more versatile. Feedback from both students and colleagues has continued to be positive. Academic, Hayley Edgington, has described the feet as “fantastic” and a “welcomed addition to our teaching”.

You can find out more about the Maker Space here.

For all press office enquiries please email communications@salford.ac.uk.

Share: